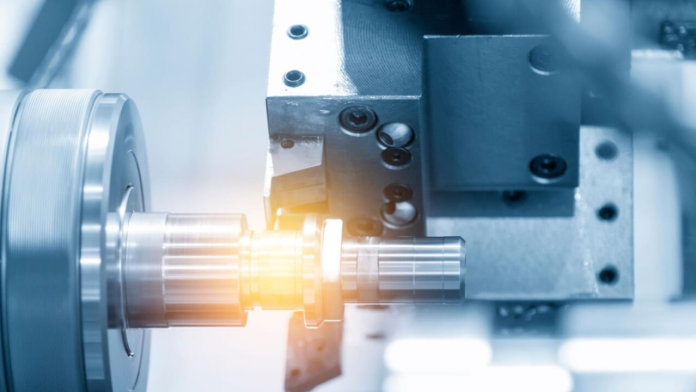

CNC turning is a specific form of precision machining wherein a cutter eliminates material by making touch with the spinning workpiece. The motion of the equipment is managed with the aid of computer instructions, taking into consideration intense precision and repeatability.

Turning is specific to CNC milling, wherein the cutting tool rotates and is directed from multiple angles at the workpiece, which is usually stationary. Due to the fact CNC turning involves rotating the workpiece in a chuck, it is typically used to create spherical or tubular shapes, achieving a long way more correct rounded surfaces than could be feasible with CNC milling or different approaches.

Although 3ERP specializes in precision machining for metals, it can also handle CNC turning for plastic components. The most machinable metal, aluminum, is frequently used to make mechanical and aspect components, which are frequently turned using CNC technology. Aluminum can be used to create products with exceptional surface finishes, high strength, and precision.

Parts Made by Using CNC Turning

The tooling is used with a CNC lathe device hooked up to a turret. This aspect is programmed to make certain moves and remove fabric from uncooked substances till the preferred 3-D version is formed. Like CNC milling, CNC turning may be used for the fast manufacture of both prototypes and quit-use elements.

CNC turning is a flexible machining technique extensively used throughout industries to create a diverse range of components with precision and efficiency. Here are some major sorts of parts that can be correctly manufactured using CNC turning:

Shafts and Axles

CNC turning is typically hired to produce cylindrical shafts and axles which might be indispensable to numerous mechanical systems. Those elements require precise dimensions, and clean surfaces, and often feature keyways or splines for coupling with different additives. Used for transmission shafts in automotive programs, force shafts in equipment, and rotor shafts in aerospace.

Bushings and Bearings

Description: Bushings and bearings are critical components that require accurate machining to ensure proper match and capability. CNC turning is used to create these components with precise internal and outside dimensions, essential for decreasing friction and wear. Used for automotive bearings, business bushings, and gadget tool additives.

Connectors and Fittings

CNC turning is right for manufacturing connectors and fittings that facilitate the assembly of various additives or systems. Those parts regularly require threaded or tapered capabilities for comfortable joining and sealing. Used for hydraulic fittings, pneumatic connectors, and plumbing additives.

Pins and Fasteners

CNC turning is applied to create various sorts of pins and fasteners that are vital for mechanical assemblies. These components can consist of functions like grooves or knurls for greater grip or threaded sections for cozy attachment. Used for dowel pins, locating pins, and fasteners utilized in automotive and business settings.

Valve and Pump Components

CNC turning is crucial for manufacturing components used in valves and pumps, in which precise inner and outside features are vital for fluid management and sealing. Used for valve our bodies, pump housings, and fluid control components in numerous industries such as oil and fuel, chemical processing, and utilities.

Rotors and Discs

CNC turning can generate rotors and discs utilized in mechanical and automotive applications. Those components require precision machining for dimensional accuracy, flatness, and stability to ensure clean operation. Used for brake rotors, turbine discs, and flywheels in automobile, aerospace, and strength era sectors.

Summary

CNC turning is a versatile and unique machining method that may produce a huge kind of elements starting from simple shafts and bushings to complex valve components and rotors. It gives blessings along with excessive accuracy, repeatability, and the ability to handle distinct materials correctly. By way of leveraging CNC turning, manufacturers can obtain efficient production approaches, and regular parts, and meet stringent layout specs throughout numerous industries including automotive, aerospace, production, and past.